The particular feature of forestry cranes or junkyards means that actuator movement is extremely fast, in very rigorous operating conditions.

Their load-bearing capacity in static conditions does not have to be very high, and the most economically viable solution is given priority. Given these particularities, overcentre valves are not used, so the control valve is required to withstand the load during downward movement. The use of special slides is common, as is an optimisation of the use of anti-shock and anti-cavitation valves in control valve elements.

The use of proportional control valves with electric joysticks, compensated elements (which facilitate parameter controls such as the maximum speed of the different movements), acceleration and deceleration ramps, alarms, etc., is becoming more and more common. Hydraulic issues still exist, so experience in control valve configuration is essential.

- In addition to extensive customisation possibilities for hydraulic manifolds, INTERSEAL also offers the option of having these hydraulic manifolds comply with the specifications required by international certifying bodies. The manifolds can also be supplied with such certification.

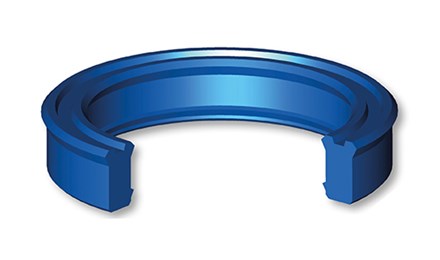

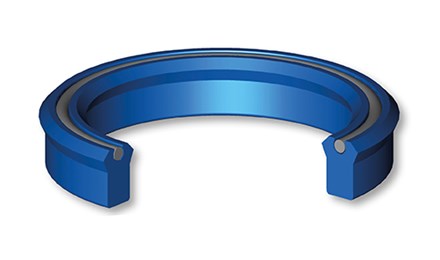

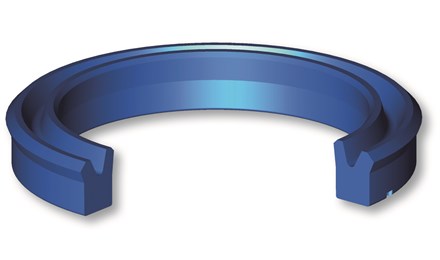

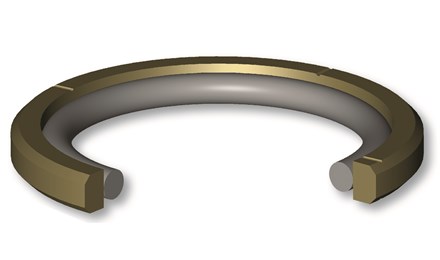

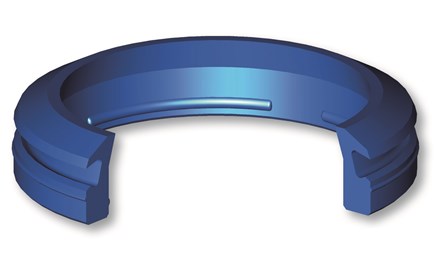

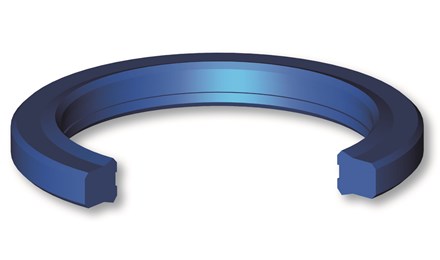

CP collar, Polyurethane collar with symmetrical lips Application: for rods and pistons.

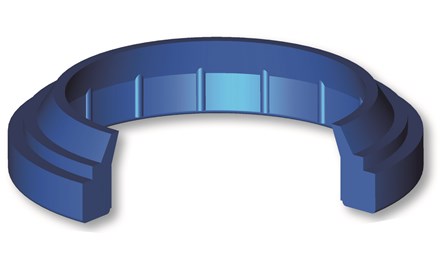

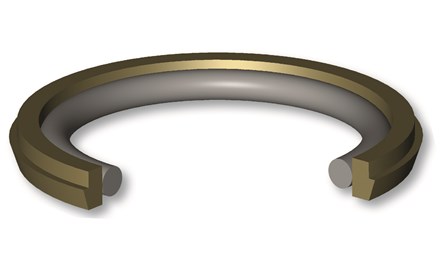

CPN polyurethane collar, Polyurethane collar with symmetrical lips Application: for rods and pistons with energising spring.

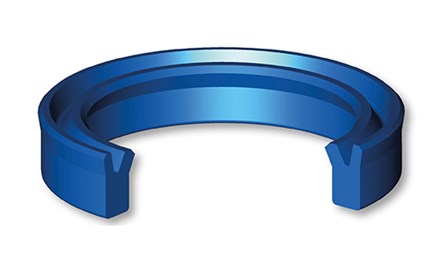

CPV polyurethane collar, Polyurethane collar with asymmetrical lips for rod application.

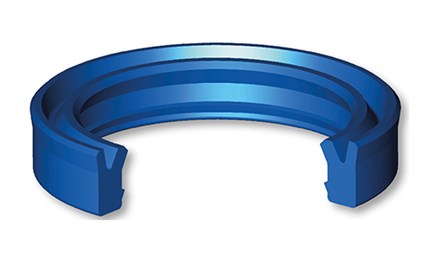

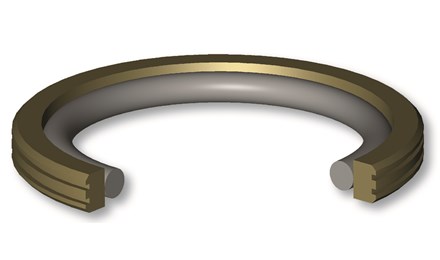

CPV2 double-lip collar, Polyurethane double-lip locking collar for rods

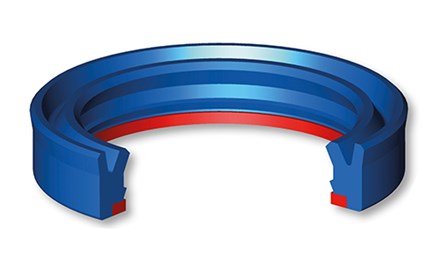

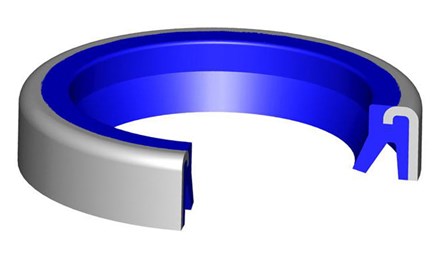

CPVA ring collar, Polyurethane double-lip locking collar For rods with anti-extrusion ring

VP angle joint packing, NBR nitrile rubber V-angle joint packing with natural cotton.

ISV single-acting seal, Single-acting rod seal FILLED PTFE + NBR OR FKM

ISVD double-acting seal, Double-acting rotary rod seal FILLED PTFE + NBR OR FKM

ISVR double-acting seal. Double-acting rotary rod seal FILLED PTFE + NBR OR FKM

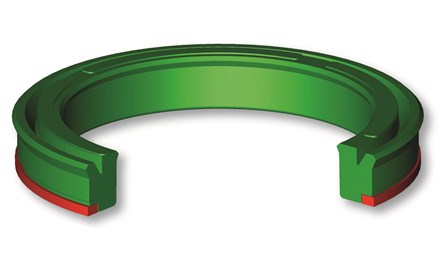

CPE piston collar, Polyurethane collar for single-acting asymmetrical lip piston.

CPEA piston collar, Polyurethane collar for single-acting asymmetrical lip piston with anti-extrusion ring.

CPEG piston collar, Polyurethane collar for single-acting asymmetrical lip piston and guide

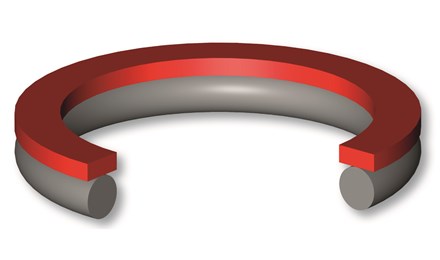

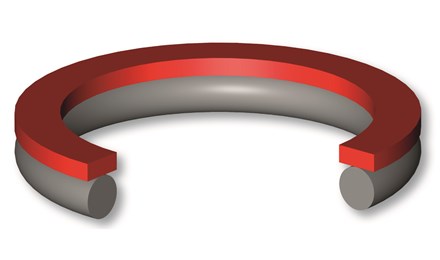

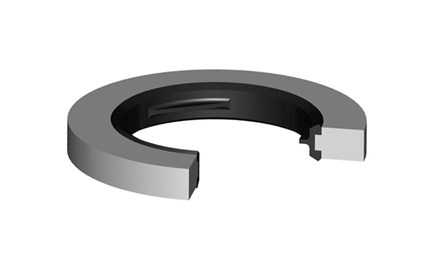

ISP piston seal, Double-acting PTFE seal for static or semi-dynamic applications FILLED PTFE + NBR OR FKM

ISPS piston seal, Single-acting PTFE seal for static or semi-dynamic applications FILLED PTFE + NBR OR FKM

ISPR piston seal, PTFE rotary piston seal FILLED PTFE + NBR OR FKM

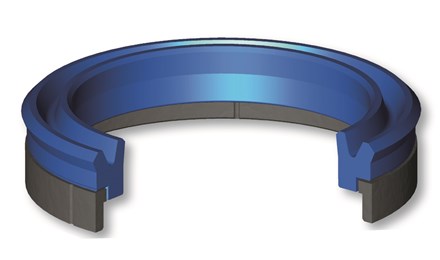

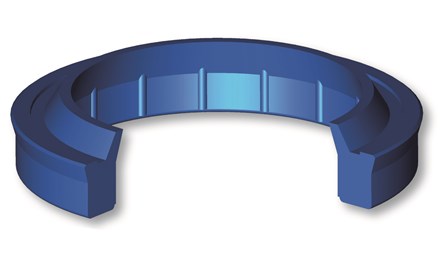

ISPQ piston seal, Three-part double-acting piston seal, FILLED PTFE + NBR OR FKM

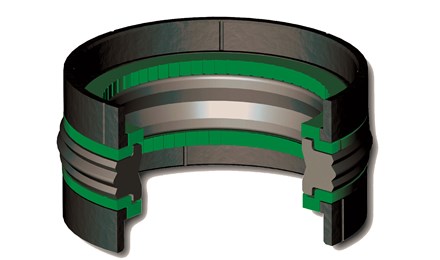

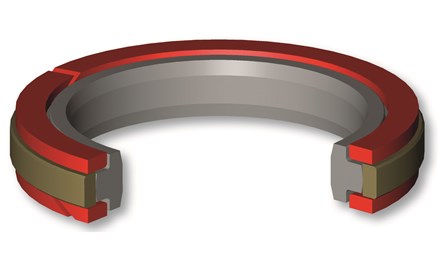

PDG piston seal, Five-element double-acting piston seal with guide ring.

PDL piston seal, Three-element double-acting piston seal, rubber canvas with guide ring

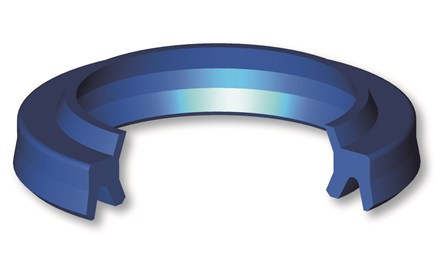

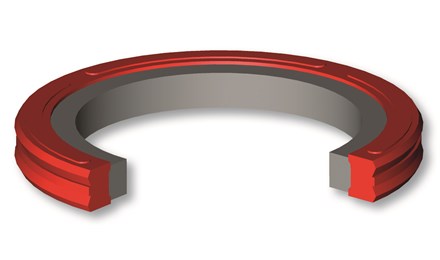

PDP piston seal, Double-acting polyurethane piston seal Hardness: 97 Shore

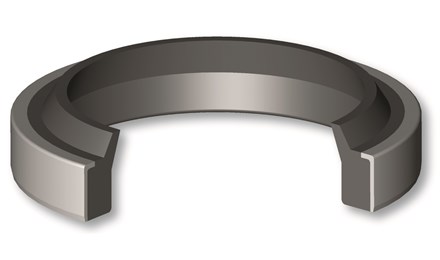

PDTG piston seal , Double-acting piston seal Polytetrafluoroethylene PTFE + Bronze.

PDPC piston seal, Double-acting piston seal, Polyurethane 97 Sh+NBR

RGM rubber wiper, NBR 90 Sh rubber wiper for steel rod with metal core.

RP1 rod wiper, Rod wiper with external sealing lip. Polyurethane. 93 Shores

RPM rod wiper, Rod wiper with metallic steel exterior. Polyurethane. 93 Shores

SAC rod wiper, SAC rod wiper with external sealing lip. Polyurethane. 93 Shores

FSP cylinder guide, Guide ring for plunger cylinder. Acetal resin with glass fibre.

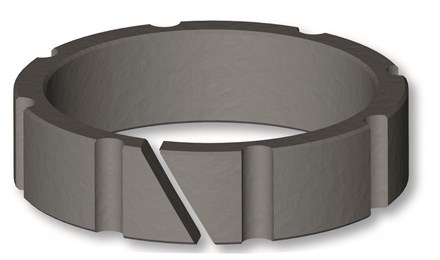

GER piston guide, Cut piston guide ring. Acetal resin with glass fibre

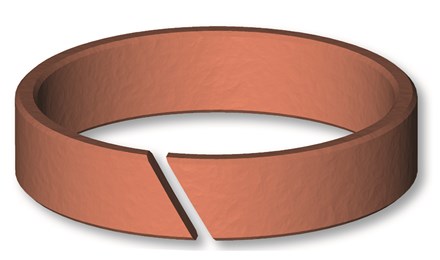

GRF piston rod guide, Rod guide ring and cut piston. Phenolic resin with natural cotton

GR piston rod guide, Rod guide ring and cut piston. Acetal resin with glass fibre.

Bonded seal seals, Bonded seal seals, NBR, FKM, in steel and stainless steel.

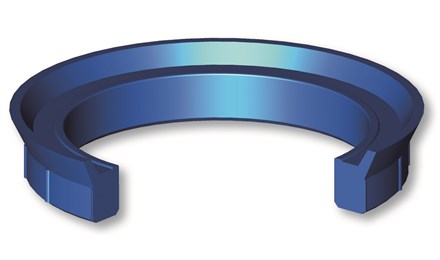

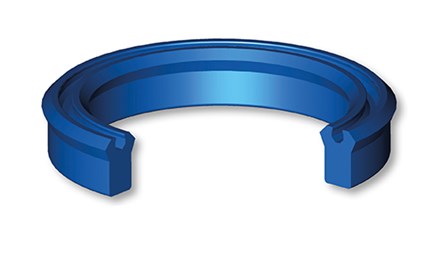

OP double-acting seal, Double-acting seal for rod and piston. Polyurethane Hardness: 93 Shore

PFS static seal, Static seal for SAE polyurethane fastener Hardness: 93 Shore A

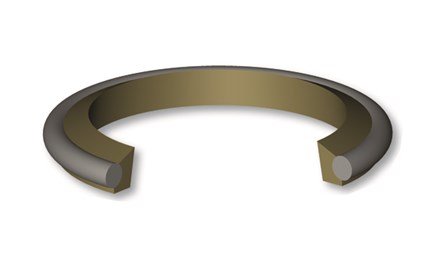

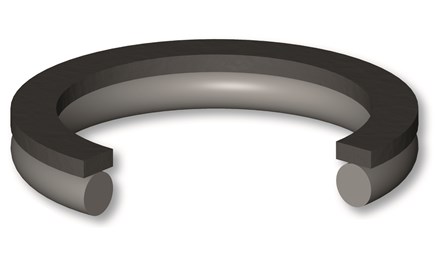

O-rings, O-rings, NBR 70/90 Sh. -30ºC+ 110ºC, Silicone MQ -60ºC + 230ºC, Viton FKM -20ºC + 200ºC.

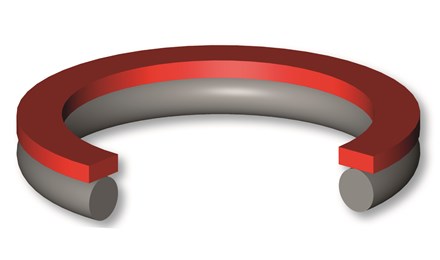

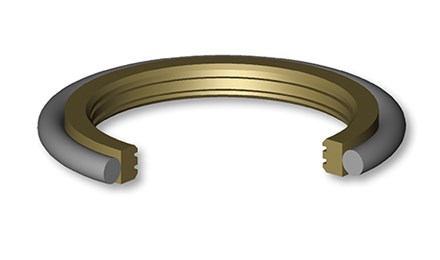

Q-ring seal, Four-lip square seal, Nitrile rubber NBR Hardness: 70 Shore

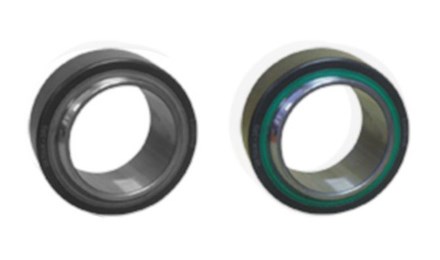

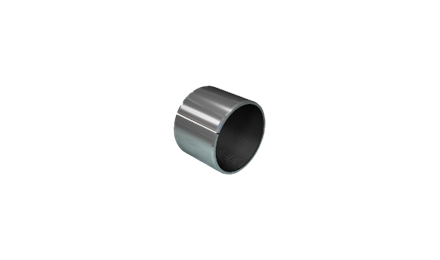

FIMBU bushing, Filled PTFE base, sintered CuSn8 bronze coating, low-carbon steel support.

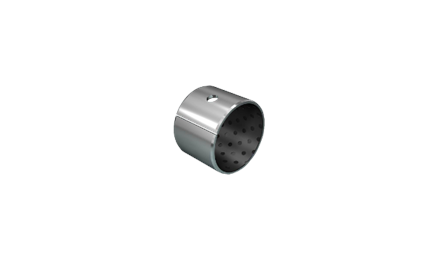

FIMBX bushing, Low-carbon support with porous and sintered sliding coating, which is in turn impregnated with a resin-acetal coating.

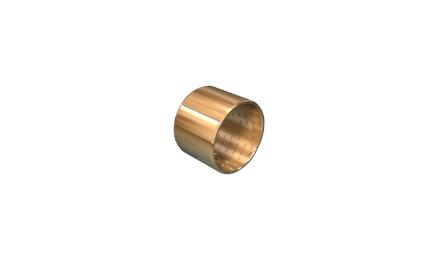

FINBW-BRM bushing, The bearings of the BRM-10 series are made entirely of CuSn8 bronze.

DIN 648 - G SERIES ISO 6124/1 WITH GREASE NIPPLE COUPLING: STEEL ON STEEL

DIN 648, EW SERIES ISO 6124/1 WITH GREASE NIPPLE COUPLING: STEEL ON STEEL

WELD-ON ROD END DIN 648, E SERIES WITH GREASE NIPPLE COUPLING: STEEL ON STEEL STAMPED ST52-3 STEEL END

WELD-ON ROD END DIN 648, E SERIES WITH GREASE NIPPLE COUPLING: STEEL ON STEEL STAMPED ST52-3 STEEL END

WELD-ON ROD END DIN 648, E SERIES WITH GREASE NIPPLE COUPLING: STEEL ON STEEL STAMPED ST52-3 STEEL END

WELD-ON ROD END DIN 648, E SERIES WITH GREASE NIPPLE COUPLING: STEEL ON STEEL STAMPED ST52-3 STEEL END

WELD-ON ROD END CETOP STANDARD WITH GREASE NIPPLE COUPLING: STEEL ON STEEL ST52-3 STEEL END

THREADED ROD END HEAD DIN 648, E SERIES WITH GREASE NIPPLE COUPLING: STEEL ON STEEL END WITH C 45 STAMPED STEEL END

THREADED ROD END WITH GREASE NIPPLE COUPLING: STEEL ON STEEL END WITH C 45 STAMPED STEEL END

THREADED ROD END WITH GREASE NIPPLE COUPLING: STEEL ON STEEL END WITH C 45 STAMPED STEEL END

THREADED ROD END ISO 6982 - DIN 24338 CETOP STANDARD WITH GREASE NIPPLE COUPLING: STEEL ON STEEL WITH C 45 STAMPED STEEL END

THREADED ROD END DIN 24555 - ISO 6124/1 E SERIES CETOP STANDARD WITH GREASE NIPPLE COUPLING: STEEL ON STEEL WITH C 45 STAMPED STEEL END

THREADED ROD END WITH GREASE NIPPLE COUPLING: STEEL ON STEEL WITH C 45 STAMPED STEEL END

THREADED ROD END WITH GREASE NIPPLE COUPLING: STEEL ON STEEL END WITH C 45 STAMPED STEEL END

THREADED ROD END WITH GREASE NIPPLE COUPLING: STEEL ON STEEL END WITH C 45 STAMPED STEEL END

THREADED ROD END DIN 648 - E SERIES - ISO 6126 WITH GREASE NIPPLE COUPLING: STEEL ON STEEL WITH C 45 STAMPED STEEL END

THREADED ROD END DIN 648 - E SERIES - ISO 6126 WITH GREASE NIPPLE COUPLING: STEEL ON STEEL WITH C 45 STAMPED STEEL END

THREADED ROD END DIN 648 - E SERIES - ISO 6126 MAINTENANCE-FREE WITH GREASE NIPPLE COUPLING: CHROME PLATED STEEL WITH PTFE FABRIC WITH C 45 STAMPED STEEL END

THREADED ROD END DIN 648 - E SERIES - ISO 6126 MAINTENANCE-FREE WITH GREASE NIPPLE COUPLING: CHROME PLATED STEEL WITH PTFE FABRIC WITH C 45 STAMPED STEEL END

THREADED ROD END DIN 648 - E SERIES - ISO 6126 WITH GREASE NIPPLE COUPLING: STEEL ON STEEL WITH C 45 GALVANISED STAMPED STEEL END

THREADED ROD END DIN 648 - K SERIES - ISO 6126 COUPLING: STEEL ON BRONZE

THREADED ROD END DIN 648 - K SERIES - ISO 6126 COUPLING: STEEL ON BRONZE + PTFE

THREADED ROD END DIN 648 - K SERIES - ISO 6126 COUPLING: STEEL ON BRONZE

THREADED ROD END DIN 648 - K SERIES - ISO 6126 COUPLING: STEEL ON BRONZE + PTFE