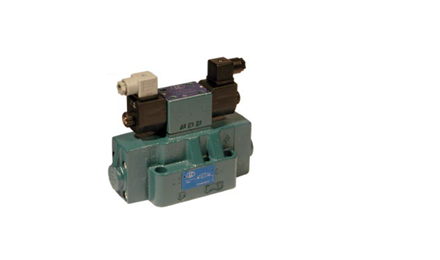

- INTERSEAL offers extensive customisation possibilities to make hydraulic manifolds fit into every single project or machine.

- In addition to extensive customisation possibilities for hydraulic manifolds, INTERSEAL also offers the option of having these hydraulic manifolds comply with the specifications required by international certifying bodies. The manifolds can also be supplied with such certification.

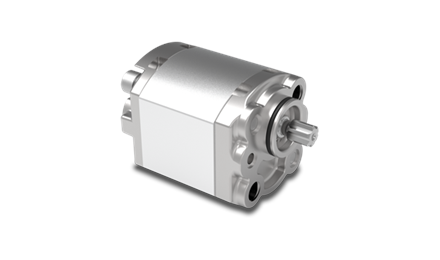

INTERSEAL offers extensive customisation possibilities to make hydraulic power packs fit into every single project or machine.

In addition to extensive customisation possibilities for hydraulic power packs, INTERSEAL also offers the option of having these hydraulic equipment comply with the specifications required by international certifying bodies. The equipment can also be supplied with such certification.

FLEXI-N piston seal, PTFE seal for static or PTFE semi-dynamic applications + Compounds Spring: AISI 301 stainless steel

FLEXI-U piston seal, PTFE seal for static or PTFE semi-dynamic applications + Compounds Spring: AISI 301 stainless steel

Bonded seal seals, Bonded seal seals, NBR, FKM, in steel and stainless steel.

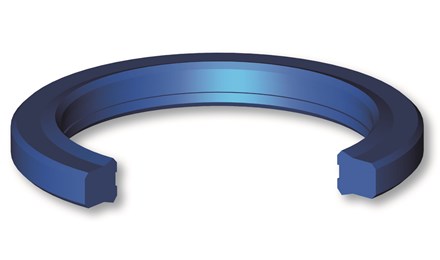

OP double-acting seal, Double-acting seal for rod and piston. Polyurethane Hardness: 93 Shore

PFS static seal, Static seal for SAE polyurethane fastener Hardness: 93 Shore A

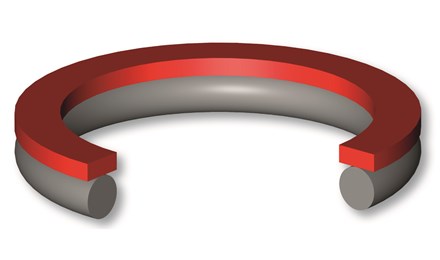

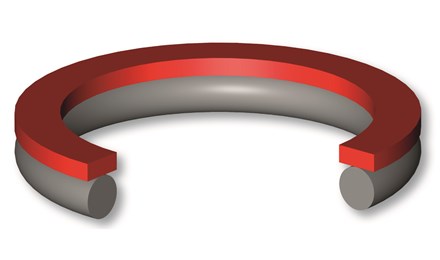

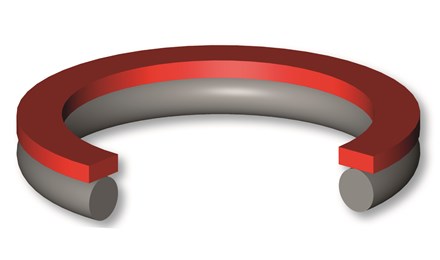

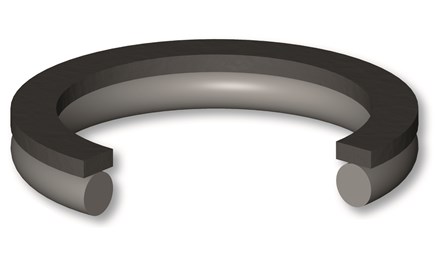

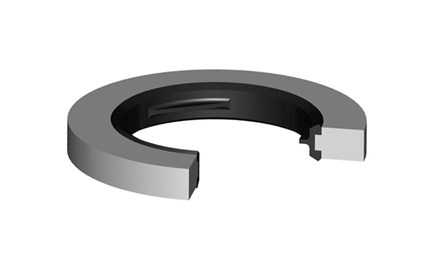

O-rings, O-rings, NBR 70/90 Sh. -30ºC+ 110ºC, Silicone MQ -60ºC + 230ºC, Viton FKM -20ºC + 200ºC.

Q-ring seal, Four-lip square seal, Nitrile rubber NBR Hardness: 70 Shore

Cord ring, Cord ring by the metre. NBR 70 Sh. A -30ºC +110ºC. Silicone MQ -60ºC + 230ºC Viton FKM -20ºC + 200 º C

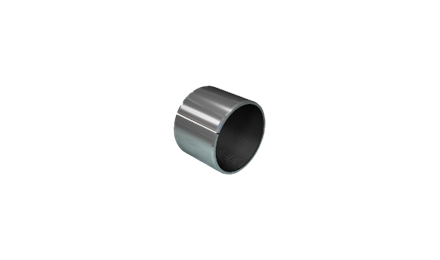

FIMBU bushing, Filled PTFE base, sintered CuSn8 bronze coating, low-carbon steel support.

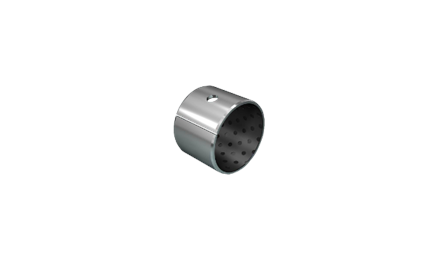

FIMBX bushing, Low-carbon support with porous and sintered sliding coating, which is in turn impregnated with a resin-acetal coating.

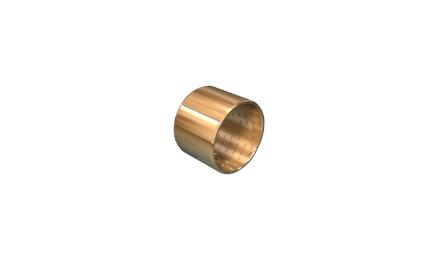

FINBW-BRM bushing, The bearings of the BRM-10 series are made entirely of CuSn8 bronze.

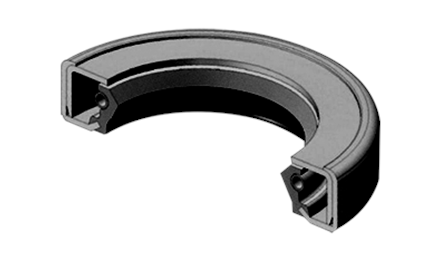

SC type

Single-lip seal manufactured according to DIN 3760 standard. The exterior is rubber-coated to increase the sealing ability with the pocket.

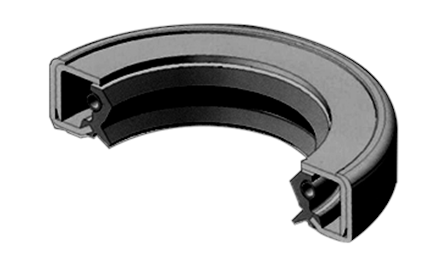

TC type

Double-lip seal manufactured according to DIN 3760 standard. The anti-dust lip design protects from external contamination. The exterior is rubber-coated for increased sealability with the pocket.

SB type

Single-lip seal. The exterior is finished in sheet metal. Designed to absorb temperature and facilitate assembly. Manufactured according to DIN 3760 standard with phosphate coated sheet.

TB type

Double-lip seal. The exterior is finished in sheet metal. Designed to withstand temperatures and facilitate assembly. Manufactured according to DIN 3760 standard with phosphate coated sheet, with anti-dust lip.

SA type

Single-lip seal. The exterior is finished in sheet metal and reinforced. Designed to withstand temperatures, heavy loads and dirtier environments, and facilitate assembly.

TA type

Single-lip seal. The exterior is finished in sheet metal and reinforced. Designed to withstand temperatures, heavy loads and dirtier environments, and facilitate assembly, with anti-dust lip.

TCN type

Double-lip, special construction seal to withstand pressures up to 11 bars. The exterior is rubber-coated to increase the sealing ability with the pocket.

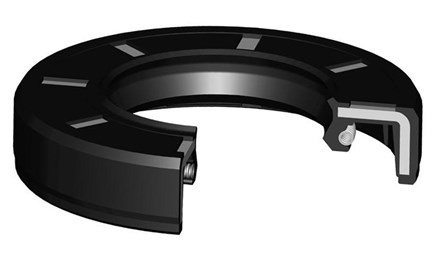

DC type

Working double-lip seal with two springs. Designed to separate two fluids. Great sealing power for double sealing. Commonly used in water pumps and crankcases to separate two fluids.

VG type

Shutter-type springless single-lip seal with ribbed outer lip. Specifically designed to protect against external contamination. The outer ribbing facilitates assembly and absorbs temperature expansion.

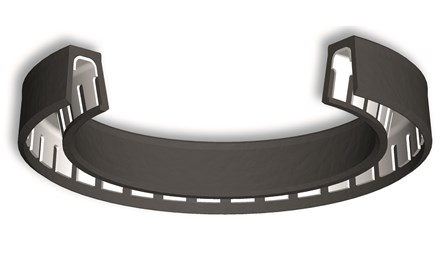

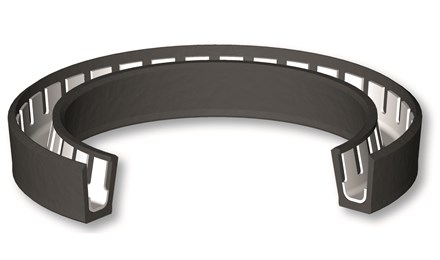

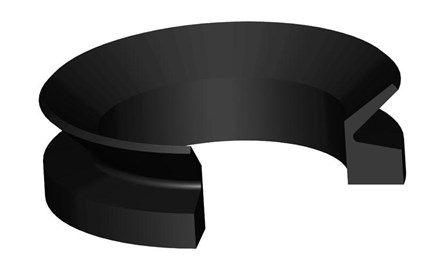

VA, VA profile Standard design. Available in the widest range of materials and measurements (from Ø9.5 up to Ø2.020 mm).

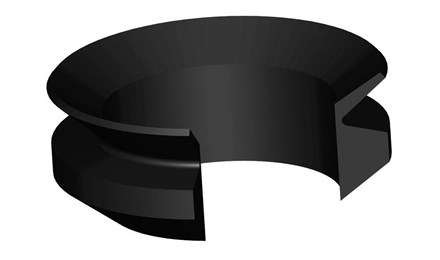

VS, VS profile The lip is exactly the same as in the VA, but the housing is more robust. As standard as the previous one, but in a smaller measurement range (up to Ø210 mm.)

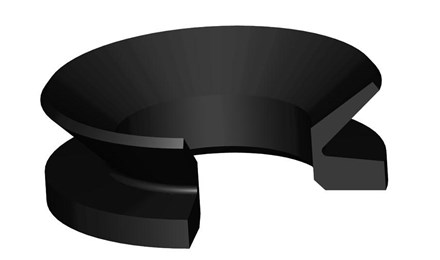

VL, VL profile Geometrically similar design to the VA but with reduced cross-section for small housings. Manufactured in a single section ranging from Ø135 up to Ø410 mm.

RB, The design of the RB seal is based on many years of experience in this type of applications, NBR OR FKM.