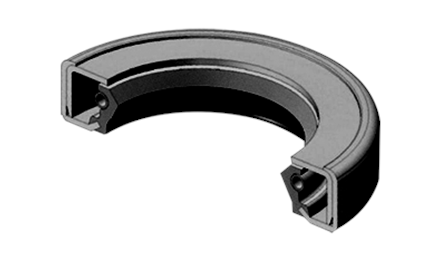

SC type

Single-lip seal manufactured according to DIN 3760 standard. The exterior is rubber-coated to increase the sealing ability with the pocket.

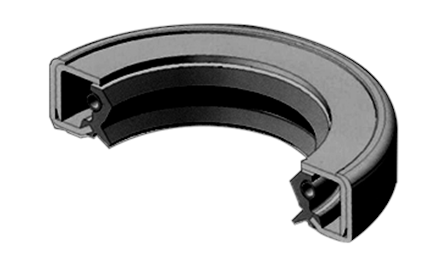

TC type

Double-lip seal manufactured according to DIN 3760 standard. The anti-dust lip design protects from external contamination. The exterior is rubber-coated for increased sealability with the pocket.

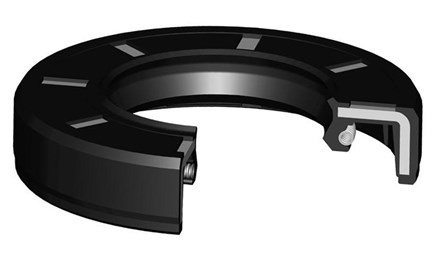

SB type

Single-lip seal. The exterior is finished in sheet metal. Designed to absorb temperature and facilitate assembly. Manufactured according to DIN 3760 standard with phosphate coated sheet.

TB type

Double-lip seal. The exterior is finished in sheet metal. Designed to withstand temperatures and facilitate assembly. Manufactured according to DIN 3760 standard with phosphate coated sheet, with anti-dust lip.

SA type

Single-lip seal. The exterior is finished in sheet metal and reinforced. Designed to withstand temperatures, heavy loads and dirtier environments, and facilitate assembly.

TA type

Single-lip seal. The exterior is finished in sheet metal and reinforced. Designed to withstand temperatures, heavy loads and dirtier environments, and facilitate assembly, with anti-dust lip.

TCN type

Double-lip, special construction seal to withstand pressures up to 11 bars. The exterior is rubber-coated to increase the sealing ability with the pocket.

DC type

Working double-lip seal with two springs. Designed to separate two fluids. Great sealing power for double sealing. Commonly used in water pumps and crankcases to separate two fluids.

VG type

Shutter-type springless single-lip seal with ribbed outer lip. Specifically designed to protect against external contamination. The outer ribbing facilitates assembly and absorbs temperature expansion.

Exterior fastening covers. With various specifications (RCA, END CAPS, CAPELLOTI) manufactured for the end-of-stroke fastening of reducers. They can be manufactured in various materials, such as FPM, NBR, VMQ, VMQ.