Seal manufacturing

INTERSEAL has incorporated new seal manufacturing equipment, which guarantees maximum efficiency and development of new profiles.

MINIMUM COST

MAXIMUM RELIABILITY

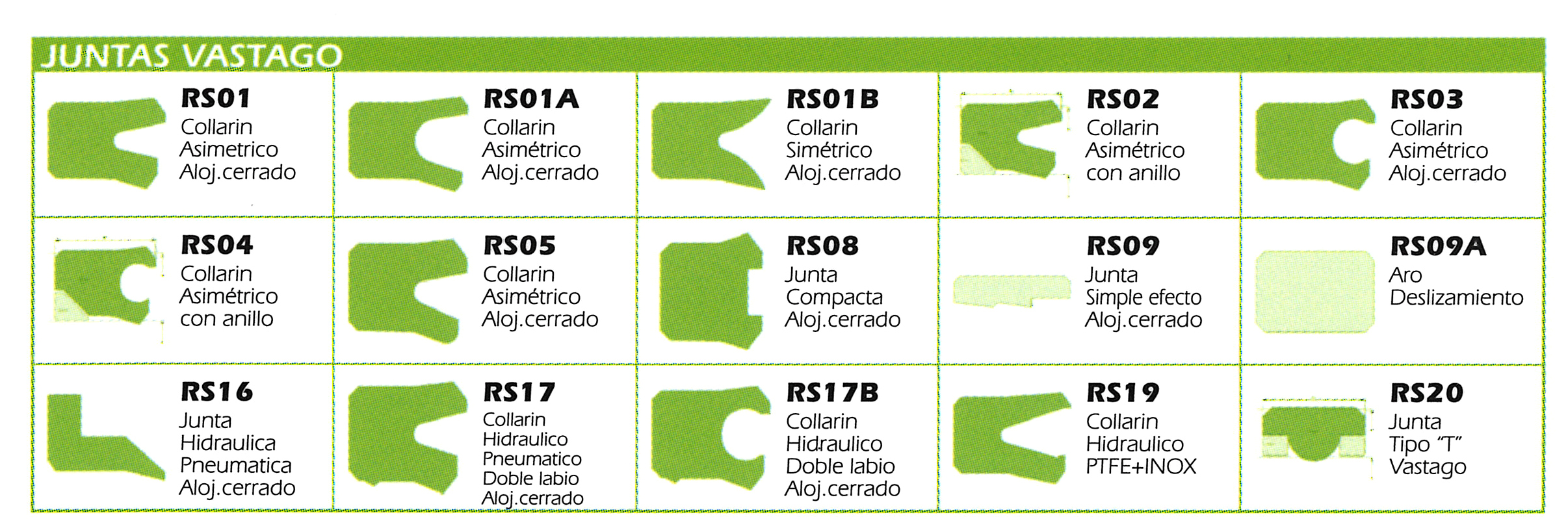

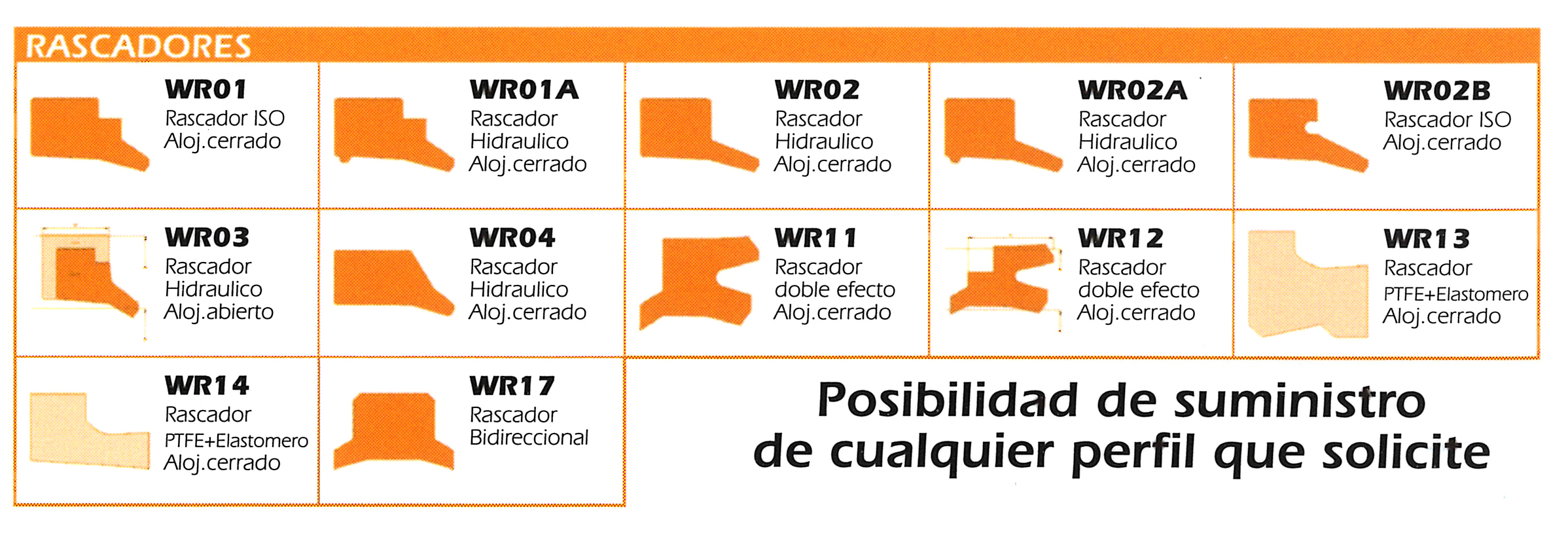

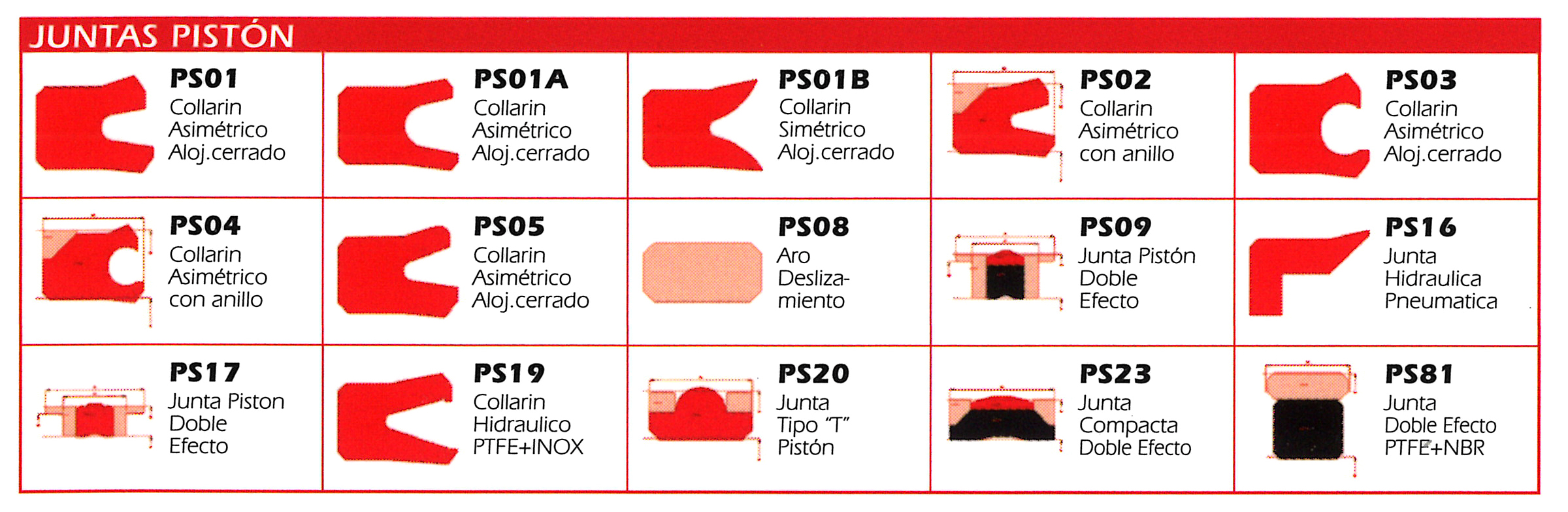

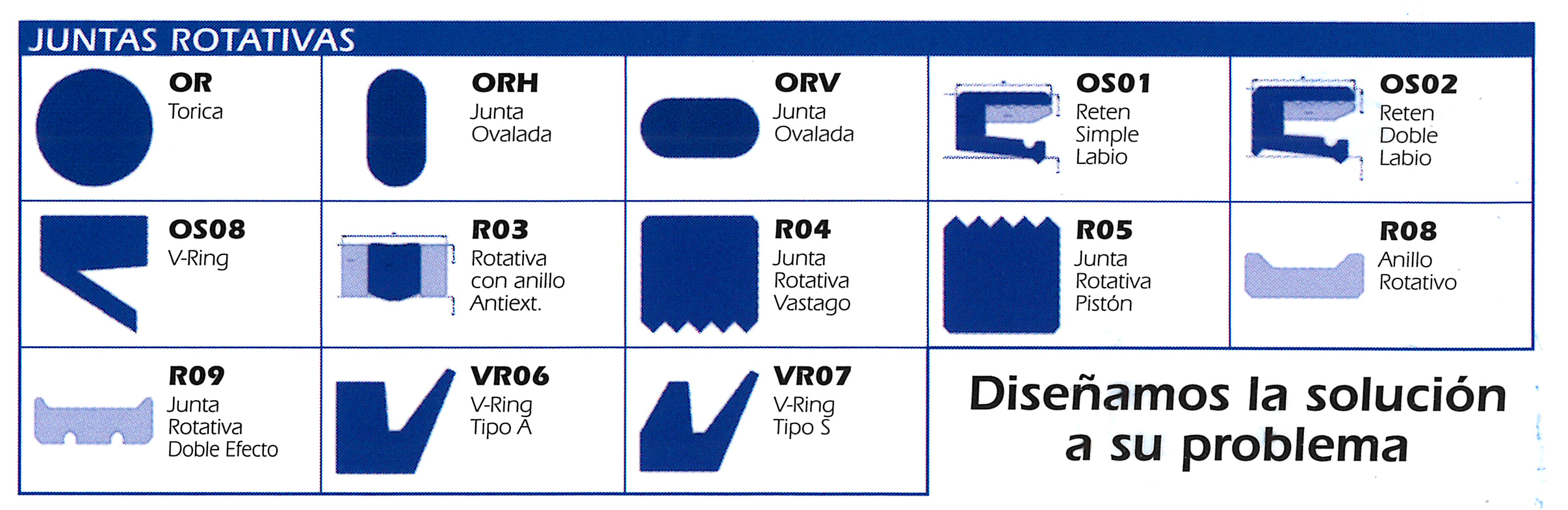

This state-of-the-art equipment, equipped with the latest developments in sealing technology, has over 180 pre-established standard profiles. In addition, their design can be modified so as to manufacture the majority of circular, square, drilled, or hexagonal geometries, among others, which can then be adapted to the measurements required by the client's sector.

This new equipment allows us to manufacture practically unlimited solutions and parts without geometry limitations and in most PUR, NBR, VITON, POM, PTFE, PEEK, or UHMVV elastomer and plastic materials, among others, approved for the Chemical and Food Industry.

Examples of different profiles:

The seals can be manufactured in various types of materials, which allows sealing

all types of liquid and gaseous fluids.

Seals can be manufactured to suit a wide range of different applications

:

Dynamic: For sealing pistons and rods in reciprocating motion.

For sealing shafts and rotating seals in rotary or helical motion.

Static: As a static seal in bushings, caps, plugs, etc.